Arthor: Jia-Shuo Hsu

Advisor: Yang-Ting Shen

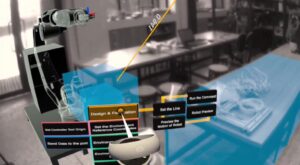

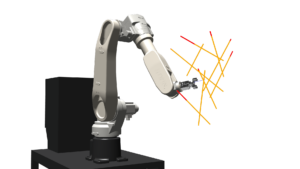

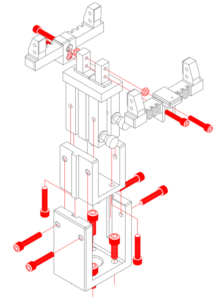

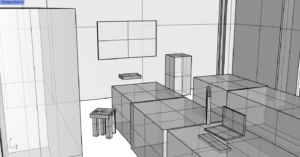

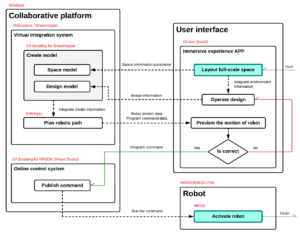

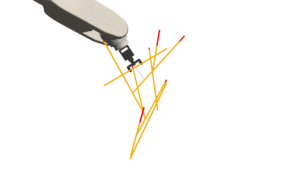

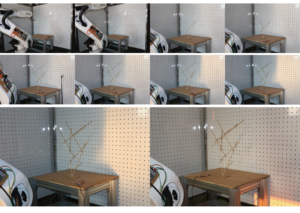

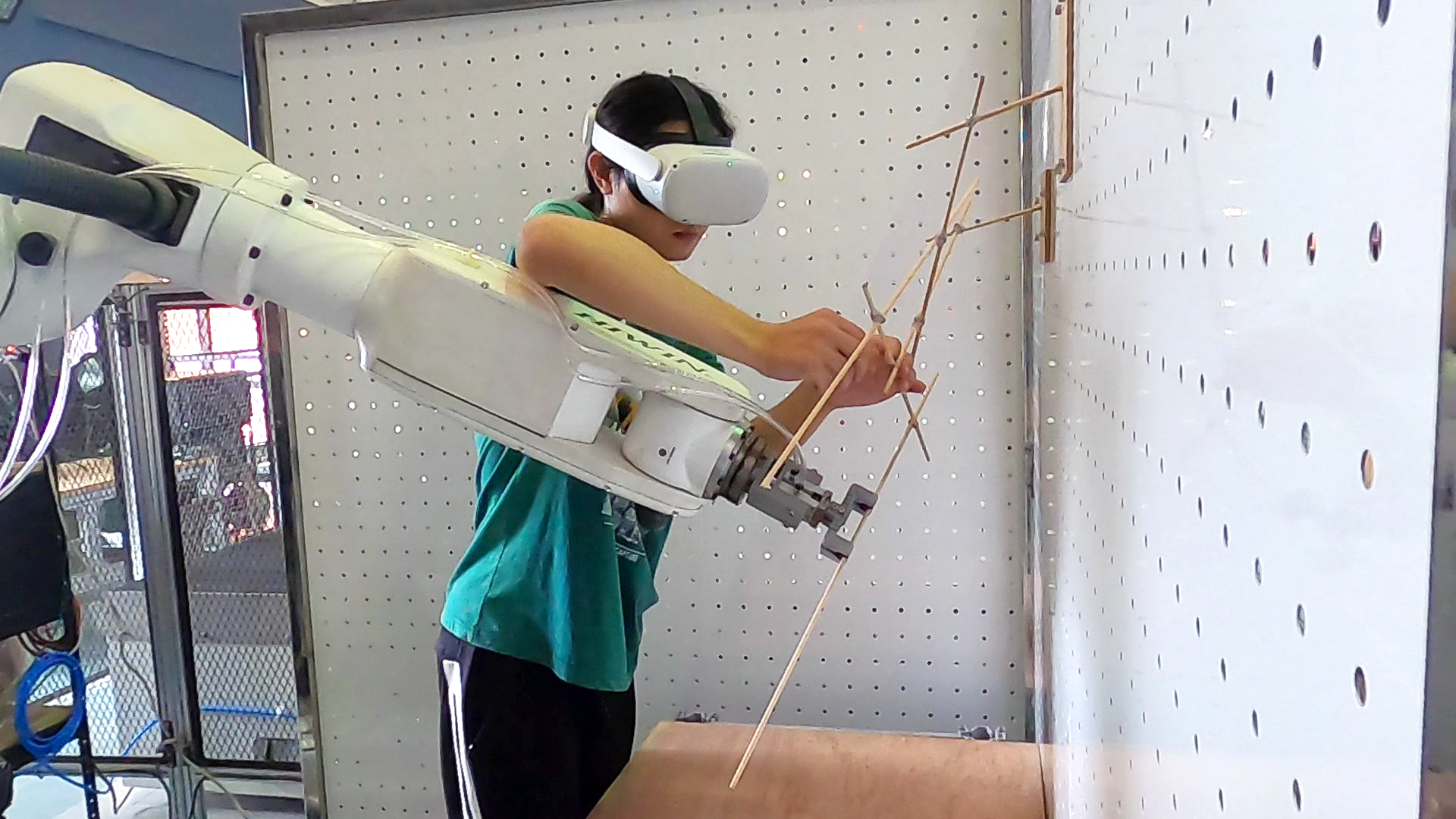

This study aims to explore a non-linear design and manufacturing system executed under human judgement using immersive technology and robotic arm production, and attempts to introduce environmental information to enable the system to adapt to the unpredictable real world environment. The research interprets the system through three categories: “virtual and physical prototyping,” “immersive design operation,” and “collaborative manufacturing process,” and integrates programming languages and parameterization software with Oculus Quest 2 and United Automation’s robots to build a mixed reality system for collaborative manufacturing processes. In terms of operation, wooden sticks are used as the manufacturing process of the system, and operators can design a line in a 3D space in the mixed reality environment, then use the robotic arm to grab the material and accurately position it on the design line.