Advisor: Yang-Ting Shen

Technical Advisor: Wei-Ting Hsiao, Chia-Ching Yen

Team Members:Yan-Fu Lin, Shun-Yu Wang, Meng-Lun Tu, Bo-Yu Gong、Yu-Lin Hsiao

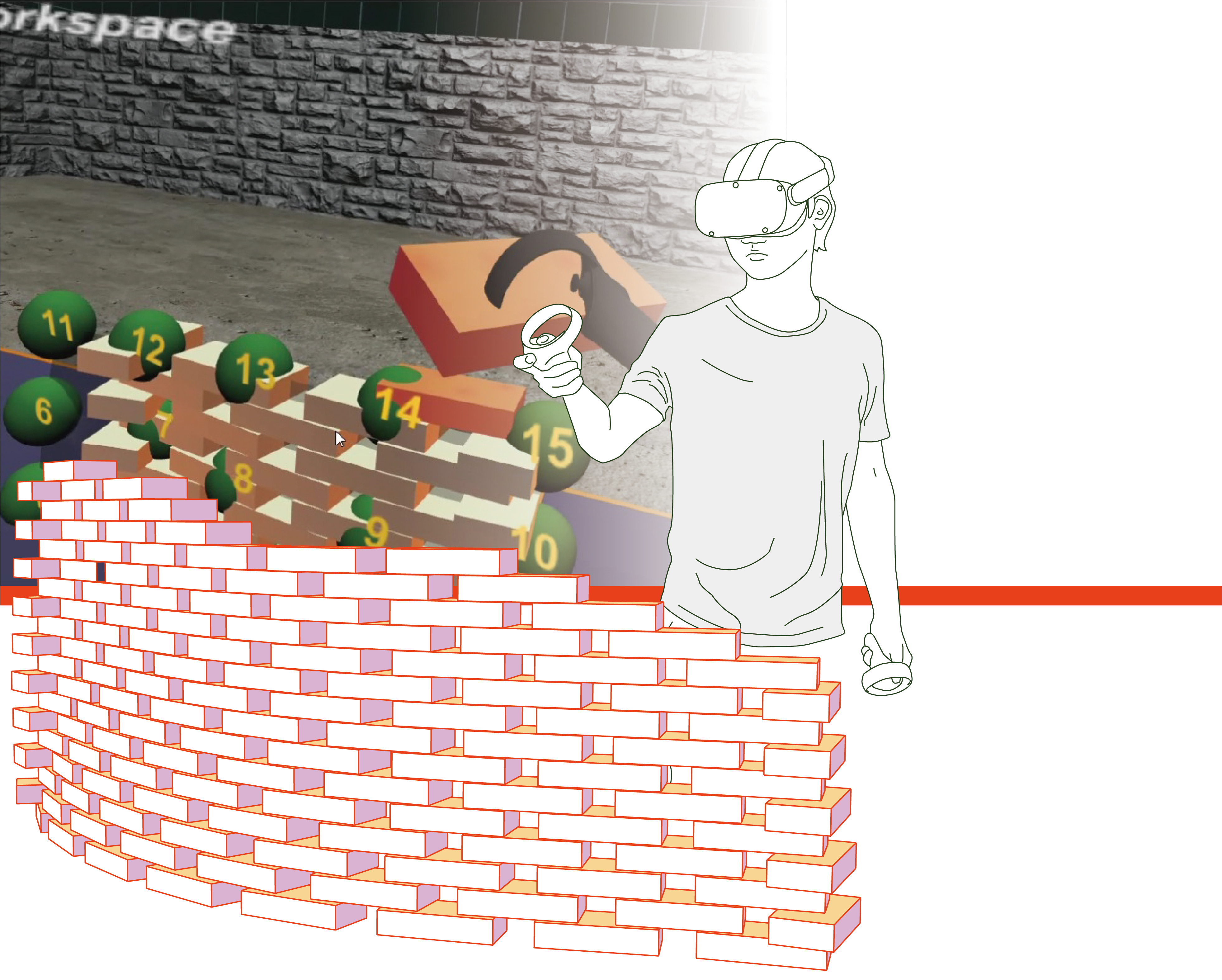

Wave Eaves is a double-curved structure formed by interlocking lumber components. The fabrication process, aided by industrial robots and utilizing parametric design tools like Grasshopper and its Kangaroo physics engine, is divided into three stages: form finding, information transfer between virtual and physical realms, and automated assembly.

Stage 1: Form Finding

The first stage of the fabrication process involves form-finding. Using Grasshopper and its Kangaroo physics engine, designers can create a virtual model of the Wave Eaves structure that accurately reflects its physical properties and structural performance. This digital representation allows architects to explore various geometric configurations while clearly understanding each design choice’s structural implications.

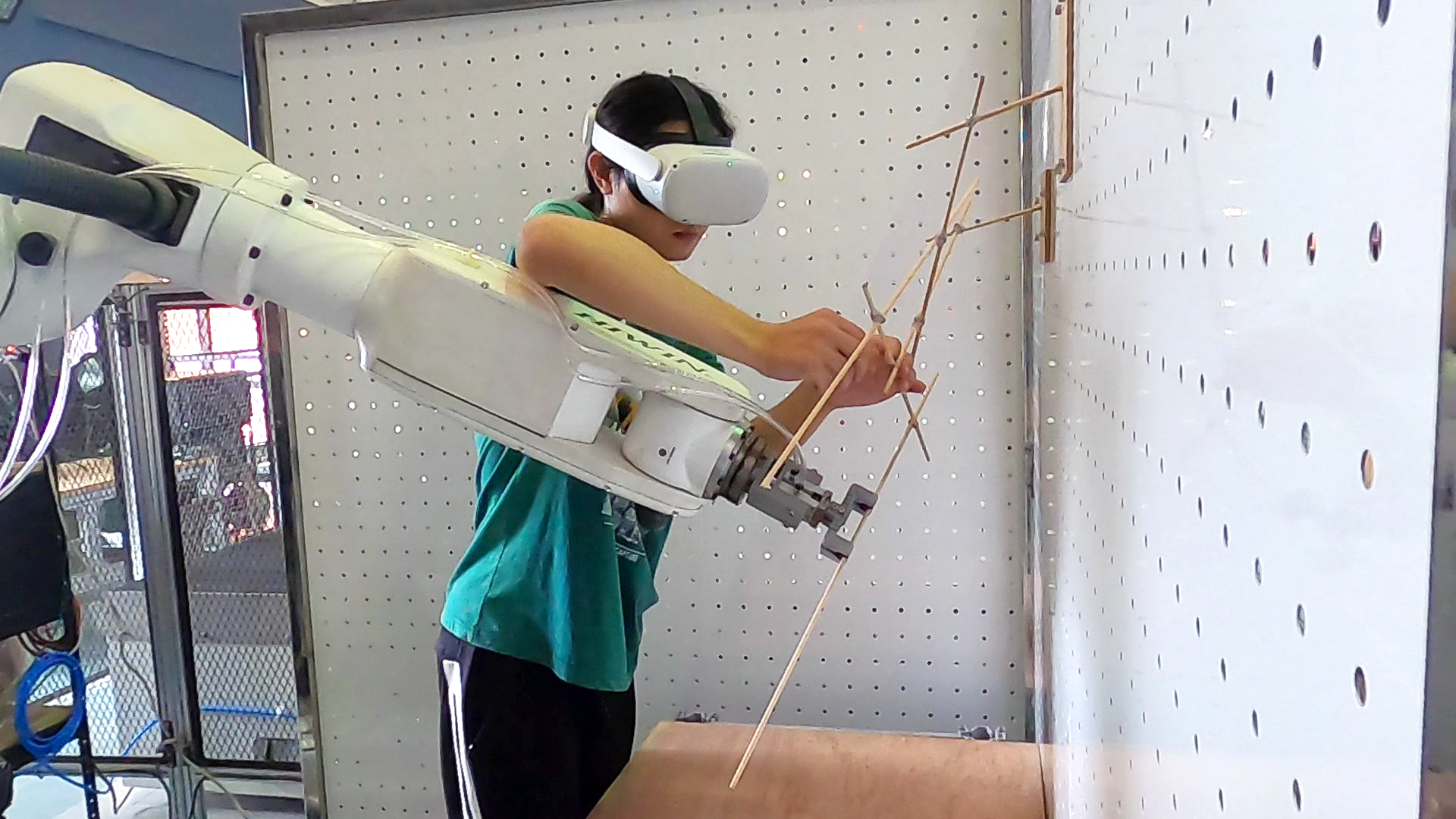

Stage 2: Interactive Information Transfer

The second stage is characterized by an interactive process of transferring information between the virtual model and the physical world. As the design evolves in the virtual space, the data is seamlessly communicated to the industrial robots, enabling them to adapt their operations accordingly. This ongoing exchange of information ensures the fabrication process remains in sync with the design intentions, allowing for high accuracy and efficiency.

Stage 3: Automated Assembly

In the third stage, human workers and industrial robots collaborate to fabricate the Wave Eaves components. The robots’ precise positioning capabilities allow them to pick up lumbers, cut them with a circular saw into the desired shape without additional fixtures, and transport them to the assembly position. Human workers then fasten the components together, completing the semi-automated process. The majority of the parts are prefabricated by the robot, requiring only minimal adjustments during on-site assembly.

Wave Eaves exemplifies the future of architectural design, combining cutting-edge robotic fabrication with the power of parametric design software. This innovative process streamlines the design and construction of complex structures, enabling architects to push the boundaries of their craft. As technology continues to advance, we can expect to see even more exciting developments in the world of architecture, forever changing the way we conceive and construct the built environment.